CFD & FSI-RG

Computational Fluid Dynamics &

Fluid Structure Interaction

Research Group

qing.xiao@strath.ac.uk +44 (0)141 548 4779

Computational Fluid Dynamics &

Fluid Structure Interaction

Research Group

qing.xiao@strath.ac.uk +44 (0)141 548 4779

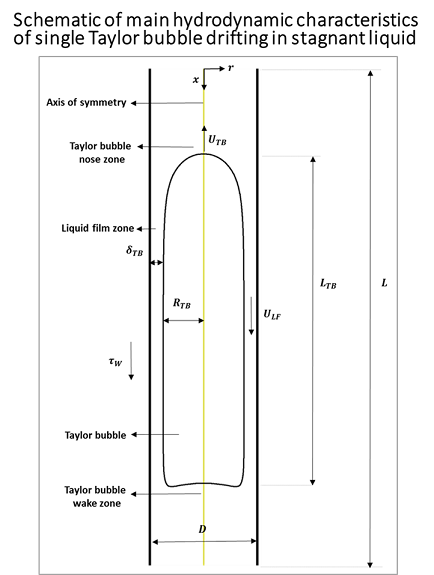

Two-Phase Slug Flow in Vertical Pipes

By Enass Massoud, Dr Qing Xiao

Multiphase flows occur in wide applications including; nuclear, chemical, and petroleum industries. One of the most important flow regime encountered in multiphase flow is the slug flow which is often encountered in oil and gas production systems. The slugging problems may cause flooding of downstream processing facilities, severe pipe corrosion and the structural instability of pipeline and further induce the reservoir flow oscillations, and a poor reservoir management.

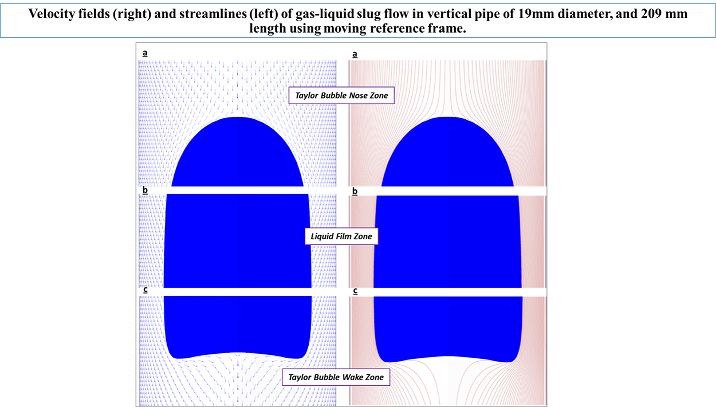

In the current project, computational fluid dynamics simulation is used to investigate two phase slug flow in vertical pipe using the volume of fluid (VOF) methodology implemented in the commercial code ANSYS Fluent. The project covers wide range of cases including; drift of single Taylor in stagnant liquid, flow of two consecutive Taylor bubbles in stagnant liquid, rise of single Taylor bubble in concurrent liquid and flow of two consecutive bubbles in concurrent fluid. The study includes both laminar and turbulent flow regimes.

The viscous, inertial, and interfacial forces have significant effect on the hydrodynamic characteristics of two-phase slug flow. These forces can have investigated by introducing a set of dimensionless numbers, namely; inverse viscosity number, Nf, Eotvos number, Eo, and Froude number, FrUTB. The project aims to investigate the main hydrodynamic features of two phase slug flow including; the shape of Taylor bubble, bubble profile, velocity and thickness of the falling film, wake flow pattern, and wall shear stress distribution over wide range of dimensionless governing groups. Correlations for the Taylor bubble rise velocity are as well developed.

Copyright © 2014 - All Rights Reserved - University of Strathclyde CFD & FSI-RG